What is a Dieline in Printing?

In the world of printing, precision is paramount, and one of the key elements that ensures accuracy and quality in packaging and print design is the dieline. Understanding what a dieline is and how it functions can significantly enhance the printing process, streamline production, and ultimately lead to more successful design outcomes.

Table of Contents

Understanding Dielines

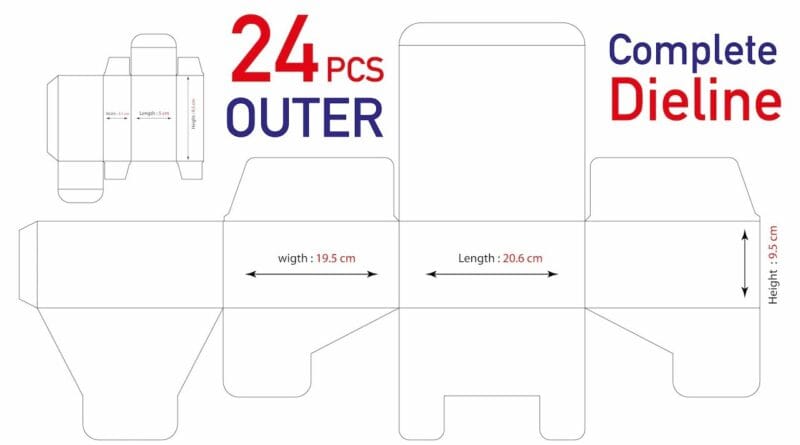

A dieline is essentially a template that outlines the layout for a printed piece, especially in packaging. It serves as a guide for cutting, folding, and assembling the final product. Dielines are used in various applications, from labels and boxes to complex multi-panel brochures. The purpose of a dieline is to provide clear instructions to printers and manufacturers about how to transform flat sheets of material into three-dimensional objects.

Components of a Dieline

A typical dieline includes several key elements:

- Cut Lines: These lines indicate where the material will be cut. They are typically represented as solid lines.

- Fold Lines: Dotted or dashed lines show where the material will be folded. These lines help ensure the packaging is correctly assembled.

- Bleed Area: This is the area beyond the cut lines that ensures the design extends to the edge of the finished product. Including a bleed prevents any white space from appearing at the edges of the product after cutting.

- Safe Zone: This is an area inside the cut lines where critical design elements (like text and logos) should be placed. Keeping these elements within the safe zone minimizes the risk of them being cut off during production.

- Registration Marks: These small marks are used to align different colors during the printing process, ensuring that each layer is printed in the correct position.

- Notes and Annotations: Sometimes, additional notes are included on the dieline to provide specific instructions or information pertinent to the printing process.

Importance of Dielines in Printing

Dielines play a crucial role in the printing industry for several reasons:

1. Precision and Accuracy

The primary function of a dieline is to ensure that all aspects of a print job are executed with precision. By providing a clear blueprint for printers, dielines help eliminate errors that could occur during cutting and folding. This precision is especially vital for packaging, where dimensions must be exact to ensure proper fit and functionality.

2. Streamlining the Production Process

A well-constructed dieline can significantly streamline the production process. It serves as a communication tool between designers and printers, allowing for a clear understanding of the project’s requirements. This reduces the risk of miscommunication and ensures that everyone is on the same page.

3. Cost Efficiency

Errors in the printing process can be costly, both in terms of materials and time. By utilizing an accurate dieline, the likelihood of mistakes is minimized, leading to reduced waste and lower production costs. This efficiency can also lead to faster turnaround times, which is crucial in a fast-paced market.

4. Design Flexibility

Dielines also provide designers with the flexibility to experiment with various shapes and structures. With a dieline, designers can visualize how their graphics will translate into three dimensions, allowing for more creative packaging solutions that stand out on the shelf.

Creating a Dieline

Creating a dieline involves several steps that require attention to detail and a good understanding of both design and printing processes.

1. Design the Artwork

Before creating a dieline, the initial step is to design the artwork that will be printed. This can include graphics, logos, and text. It’s important to consider how these elements will be affected by cutting and folding when designing the artwork.

2. Choose the Right Software

Dielines are typically created using graphic design software such as Adobe Illustrator, CorelDRAW, or specialized packaging design tools. These programs allow designers to create precise vector-based templates that are essential for accurate cutting and printing.

3. Set Up the Dieline

When setting up a dieline, follow these steps:

- Create a New Document: Start by creating a new document in your design software with the appropriate dimensions.

- Draw the Cut and Fold Lines: Use solid lines for cuts and dashed or dotted lines for folds. Ensure that these lines are clearly distinguishable from the artwork.

- Add Bleed and Safe Zones: Extend your design elements to the bleed area and ensure that important graphics stay within the safe zone.

- Include Registration Marks: Add any necessary registration marks that will help with color alignment during printing.

4. Review and Test

Before sending the dieline to print, it’s crucial to review and test the design. Create a mock-up or prototype using the dieline to ensure that all elements fit correctly and that the final product will meet expectations.

Common Mistakes to Avoid

While creating a dieline, there are several common pitfalls that designers should avoid:

1. Inaccurate Measurements

Ensure all measurements are accurate. A small error can lead to significant problems during the cutting process.

2. Overlapping Elements

Be cautious of overlapping design elements, especially in the bleed area. Overlapping can lead to unexpected results during printing.

3. Ignoring Production Techniques

Understand the printing techniques that will be used. Some methods may require specific dieline considerations that could affect the final product.

Conclusion

A dieline is a critical component in the printing and packaging process, serving as a blueprint that ensures precision, efficiency, and creativity. By understanding the elements that make up a dieline and the importance of each, designers and printers can work together seamlessly to create stunning, functional print products. Whether it’s a simple label or an intricate box design, a well-crafted dieline can make all the difference in achieving a successful print outcome. Embracing the role of dielines in printing not only enhances the quality of the final product but also enriches the creative process itself.