A Beginner’s Guide to Understanding Switchgear Components

Switchgear is a vital component of electrical power systems, ensuring the safe and efficient control, protection, and isolation of electrical circuits. Understanding the various components of electrical switchgear is essential for anyone involved in power distribution, whether in industrial, commercial, or residential settings. This guide will provide a comprehensive overview of switchgear components and their functions, while also highlighting the role of switchgear manufacturers in producing reliable equipment.

Table of Contents

What is Electrical Switchgear?

Electrical switchgear refers to a collection of devices that manage and protect electrical circuits. It serves several purposes:

- Control: It allows operators to switch circuits on and off as needed.

- Protection: It safeguards equipment from overloads and short circuits.

- Isolation: It disconnects circuits for maintenance or emergencies.

Switchgear can be categorized into two main types based on voltage levels:

- High-Voltage Switchgear: Used for voltages above 36 kV, typically found in substations and power plants.

- Low-Voltage Switchgear: Used for voltages below 1 kV, commonly utilized in residential and commercial applications.

Switchgear systems consist of various components that work together to ensure the safe operation of electrical networks.

Key Components of Electrical Switchgear

Circuit Breakers

Circuit breakers are critical components of switchgear, designed to automatically interrupt the flow of electricity in case of an overload or fault. They protect electrical circuits from damage and ensure safety. Circuit breakers can be classified into several types:

- Air Circuit Breakers (ACB): Suitable for low-voltage applications, they use air to extinguish the arc that forms when the circuit is interrupted.

- Vacuum Circuit Breakers (VCB): Common in medium-voltage systems, they extinguish arcs in a vacuum, making them reliable and efficient.

- Oil Circuit Breakers: Utilized in older systems, these devices use oil for arc suppression.

- SF6 Circuit Breakers: These are used in high-voltage applications, utilizing sulfur hexafluoride gas for insulation and arc suppression.

Fuses

Fuses serve as protective devices that prevent excessive current from flowing through a circuit. They consist of a metal wire or filament that melts when the current exceeds a certain level, breaking the circuit and preventing damage. Unlike circuit breakers, fuses must be replaced after they operate.

Switches

Switches are fundamental to electrical switchgear, allowing operators to control the flow of electricity. There are different types of switches used in switchgear systems:

- Isolators (Disconnectors): Used to isolate a circuit from the power source, ensuring safety during maintenance.

- Load Break Switches: Capable of interrupting circuits under load conditions, these switches are essential in medium-voltage applications.

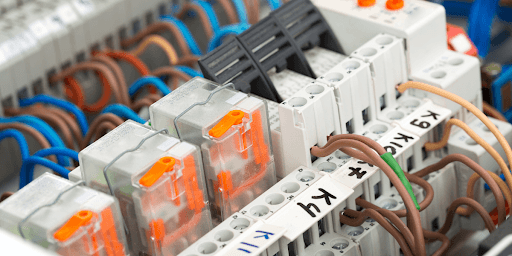

Relays

Relays are devices that monitor electrical circuits and activate circuit breakers in the event of faults. They detect conditions such as overcurrent or voltage anomalies and send signals to trip the circuit breaker, ensuring protection. There are various types of relays:

- Electromechanical Relays: Traditional relays that use mechanical action to open or close a circuit.

- Digital Relays: Modern relays that employ digital processing for faster and more accurate fault detection.

Busbars

Busbars are conductive strips that distribute electrical power to various circuits within a switchgear assembly. Made from materials like copper or aluminum, busbars minimize energy losses and improve overall system efficiency. They serve as the central point for connecting multiple components in the switchgear system.

Instrument Transformers

Instrument transformers are used to measure electrical quantities, such as voltage and current. They provide accurate readings for monitoring and protection devices. The two main types are:

- Current Transformers (CTs): These transformers measure high currents and convert them to lower, manageable levels for relays and meters.

- Voltage Transformers (VTs): VTs step down high voltages to safe levels for monitoring and protection.

Protective Devices

In addition to circuit breakers and fuses, switchgear systems incorporate various protective devices. For example, surge arresters protect against voltage spikes caused by lightning or switching operations. These devices redirect excess voltage to the ground, safeguarding the electrical system.

Control Panels

Control panels serve as the user interface for switchgear systems. They provide operators with controls, indicators, and displays to monitor the system’s operation. Operators can manually control switches and view real-time data, such as current flow and voltage levels, enabling informed decision-making.

Earthing Systems

Earthing systems are crucial for the safety of electrical installations. They provide a low-resistance path for fault currents to flow to the ground, reducing the risk of electric shock and fire. Proper earthing enhances system stability by minimizing voltage fluctuations during fault conditions.

Enclosures and Housing

The enclosures of switchgear provide physical protection for internal components. They shield the equipment from dust, moisture, and other environmental factors that could interfere with performance. Additionally, enclosures prevent unauthorized access to high-voltage components, enhancing safety.

How Does Electrical Switchgear Work?

The operation of electrical switchgear centers on managing the flow of electricity and ensuring protection against faults. Here’s a simplified overview of how switchgear functions:

- Normal Operation: Under normal conditions, electricity flows through the switchgear system via busbars and circuit breakers, allowing for controlled distribution of power to various circuits.

- Fault Detection: When a fault occurs, such as a short circuit or overload, protective relays detect the abnormal condition. These relays signal the circuit breakers to interrupt the power supply, preventing damage to the system.

- Power Isolation: In cases of maintenance or emergencies, isolators are used to disconnect specific circuits, ensuring that personnel can safely work on the equipment.

- Restoration of Power: After addressing faults or completing maintenance, circuit breakers can be reset, and power is restored to the affected circuits.

The Role of Switchgear Manufacturers

Switchgear manufacturers play a pivotal role in producing reliable and efficient switchgear systems. They design and develop various components to ensure that electrical systems operate safely and effectively. Key aspects of their contributions include:

- Innovation: Manufacturers are continuously innovating to improve the design, performance, and safety of switchgear products.

- Quality Control: Ensuring high-quality production standards is crucial for switchgear manufacturers to deliver reliable equipment that meets industry standards.

- Support and Service: Manufacturers often provide technical support, installation services, and maintenance solutions to ensure the optimal performance of their switchgear products.

Choosing reputable switchgear manufacturers is essential for obtaining reliable equipment that meets specific needs and regulatory requirements.

Conclusion

Understanding the components of electrical switchgear is essential for anyone involved in power systems. From circuit breakers to busbars, each component plays a crucial role in ensuring safe and efficient power distribution. With the support of knowledgeable switchgear manufacturers, users can enhance the reliability and performance of their electrical systems, contributing to a safer and more efficient power infrastructure. This knowledge is invaluable for those working with electrical systems, ensuring informed decisions and successful management of power distribution networks.